CONVERGING: 4th GA Meeting in Vigo, Spain

The 4th General Assembly Meeting of the CONVERGING project took place on January 15-16, 2025, in Vigo, Spain, hosted at the facilities of our partner AIMEN. Bringing together all project partners, this two-day meeting served as a crucial milestone to assess progress, exchange insights, and strategically plan the next steps for the project’s continued success. The meeting provided an excellent opportunity for collaboration, ensuring that all efforts remain aligned with the overarching objectives of CONVERGING in advancing human-robot collaboration, AI-driven manufacturing, and digital transformation.

The meeting started with a warm welcome from the project coordinator, who set the stage by presenting the agenda for the two-day discussions. This opening session established a clear framework for the topics to be covered and reinforced the collaborative spirit that defines CONVERGING. Each project partner then had the opportunity to present their respective progress, showcasing achievements and ongoing developments across different work packages. These presentations provided valuable insights into the advancements made and the challenges encountered, fostering an environment of open dialogue where constructive discussions and questions helped refine ideas and approaches.

As the sessions unfolded, the meeting was characterized by a dynamic and engaging exchange of knowledge. Partners actively participated, raising thought-provoking questions and collectively exploring solutions to any technical or operational challenges. This collaborative approach reinforced the consortium’s commitment to excellence, ensuring that any issues were promptly addressed with a shared understanding of the project’s objectives. The discussions were not only focused on technical advancements but also emphasized the broader impact of CONVERGING, particularly its role in shaping the future of intelligent manufacturing and smart industrial processes.

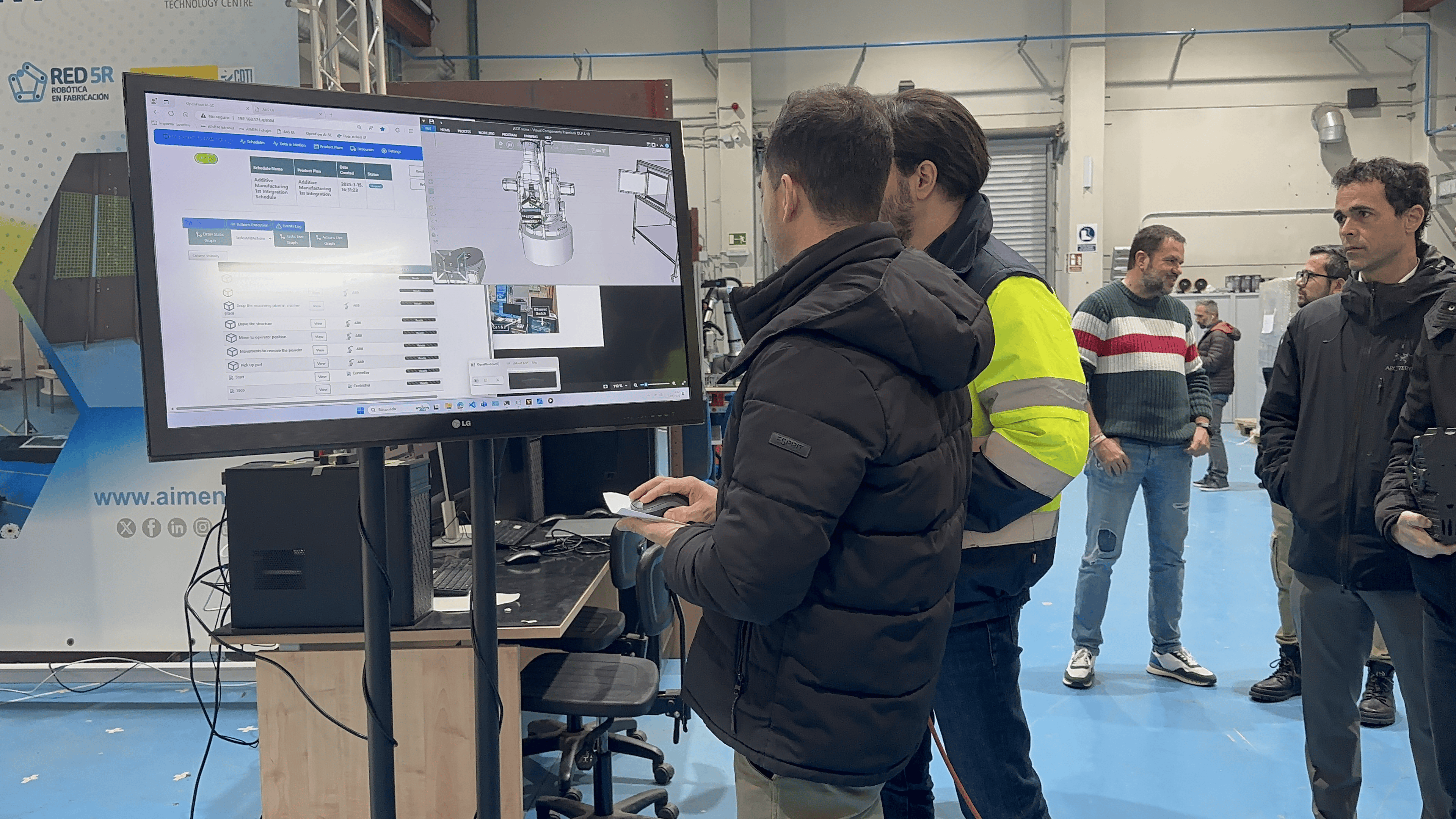

A highlight of the first day was an exclusive tour of AIMEN’s cutting-edge laboratories, where partners had the unique opportunity to witness real-world demonstrations of key technologies developed within the project. The visit included a live demonstration of human-robot collaboration in an industrial environment and a real-time digital twin simulation, showcasing how these innovations can enhance automation, efficiency, and safety in manufacturing. This hands-on experience provided a tangible understanding of how CONVERGING’s research is being translated into practical applications, further validating the project’s relevance and potential impact.

On the second day, discussions continued with a strong focus on defining the next steps for the project’s upcoming phase. Partners reflected on the progress made thus far and worked together to establish a structured roadmap for future activities. Key priorities were identified to ensure smooth execution of the upcoming tasks, aligning efforts to maximize efficiency and innovation. These strategic discussions reinforced the importance of cross-partner collaboration, as well as the collective drive to push the boundaries of digital transformation and advanced robotics within industrial settings.

The 4th General Assembly Meeting in Vigo was an essential moment for the consortium, not only to review achievements but also to strengthen the collaborative foundation that underpins the success of CONVERGING. The event highlighted the dedication and expertise of all partners, demonstrating the project’s momentum toward delivering groundbreaking technological solutions. With a strong vision for the future and a clear path ahead, the CONVERGING project remains committed to shaping the next generation of manufacturing technologies.

A special thank you goes to AIMEN for their hospitality and to all partners for their valuable contributions. As the project progresses, we look forward to further advancing our research and sharing impactful developments. Stay tuned for more updates on how CONVERGING is redefining the future of human-robot collaboration and smart manufacturing!